When it comes to cable manufacturing, one of the most important considerations is cable shielding technology. Cable shielding is used to protect cables from electromagnetic interference (EMI) and radio frequency interference (RFI), which can cause signal degradation and affect the performance of electronic equipment. There are different types of cable shielding technology available, each with its own specifications, advantages, and disadvantages. Here’s an overview of the most common types of cable shielding technology:

Foil Shielding

Foil shielding is a type of cable shielding that uses a thin layer of aluminum or copper foil to wrap around the cable. The foil provides a barrier against EMI and RFI, and is often used in combination with a braided shield for added protection. Foil shielding is typically lightweight and flexible, making it easy to work with. However, it may be more susceptible to tears or punctures than other types of shielding.

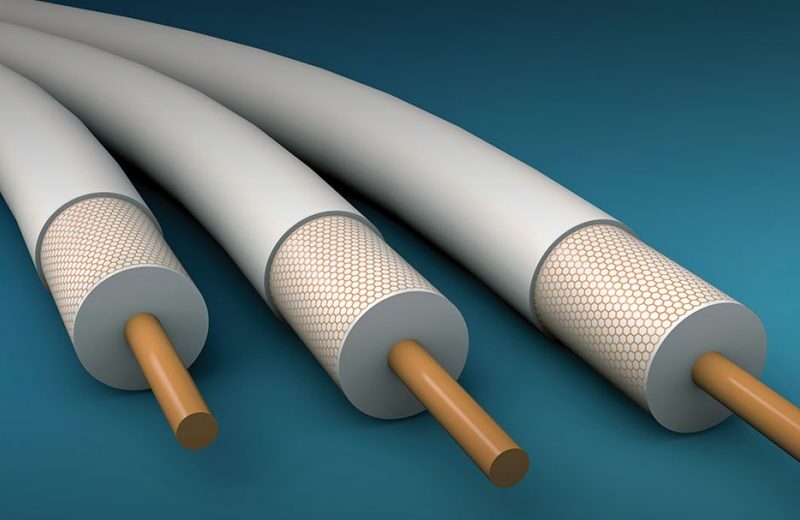

Braided Shielding

Braided shielding uses a mesh of tiny wires to wrap around the cable. The wires can be made of copper, aluminum, or other materials, and the mesh can be tightly or loosely woven depending on the desired level of protection. Braided shielding is often used in conjunction with foil shielding for added protection against EMI and RFI. Braided shielding is generally more durable than foil shielding, but it can be more difficult to work with due to its rigidity.

Spiral Shielding

Spiral shielding consists of a single wire that is wrapped around the cable in a spiral pattern. This type of shielding is less common than foil or braided shielding, but it can be effective in certain applications. Spiral shielding is often used for cables that need to be lightweight and flexible, which is also called spiral cable assembly, such as microphone cables or guitar cables. However, spiral shielding may not provide as much protection against EMI and RFI as other types of shielding.

Combination Shielding

Combination shielding is a technique that combines two or more types of shielding for added protection against EMI and RFI. For example, a cable may use both foil and braided shielding, or it may use a combination of braided and spiral shielding. Combination shielding can provide a higher level of protection than any one type of shielding alone, but it can also be more complex to manufacture and may add additional weight or rigidity to the cable.

Pros and Cons of Cable Shielding Technology

There are several advantages and disadvantages to consider when choosing a cable shielding technology for your application. Here are some of the pros and cons of the different types of cable shielding technology:

Pros:

- Cable shielding technology can improve the performance and reliability of electronic equipment by reducing interference and noise.

- Foil shielding is lightweight and flexible, making it easy to work with.

- Braided shielding is durable and provides excellent protection against EMI and RFI.

- Spiral shielding is lightweight and flexible, making it ideal for certain applications.

- Combination shielding can provide a high level of protection against EMI and RFI.

Cons:

- Foil shielding may be more susceptible to tears or punctures than other types of shielding.

- Braided shielding can be difficult to work with due to its rigidity.

- Spiral shielding may not provide as much protection against EMI and RFI as other types of shielding.

- Combination shielding can be more complex to manufacture and may add additional weight or rigidity to the cable.

When it comes to cable shielding technology, there are several types to choose from, each with its own advantages and disadvantages. By understanding the specifications and pros and cons of each type of shielding, , you can make an informed decision about which type of shielding is best suited for your application. Factors to consider include the level of protection required, the flexibility and weight of the cable, and the manufacturing complexity and cost. Ultimately, the choice of cable shielding technology will depend on your specific application requirements and budget.

In conclusion, cable shielding technology is an essential aspect of cable manufacturing that helps protect electronic equipment from EMI and RFI. The different types of shielding technology available, including foil, braided, spiral, and combination shielding, each have their own specifications, advantages, and disadvantages. By carefully considering your application requirements and the pros and cons of each type of shielding, you can choose the right cable shielding technology for your needs.

Check out our high quality cable with special shielding: