| code | Single Core |

|---|---|

| Conductor | copper |

| Nominal voltage U0/U | 1500V |

| Temperature (°C) - flexing | -40°C to +80°C |

| Color | Black, Blue, Brown, customized, Dark Blue, Gray, Green, Orange, Red, white, Yellow |

| MOQ | 500meter |

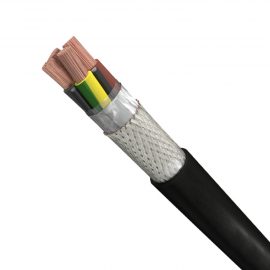

| code | Multi-Core |

|---|---|

| Conductor | copper |

| Nominal voltage U0/U | 1500V |

| Temperature (°C) - flexing | -40°C to +80°C |

| Color | Black, Blue, Brown, customized, Dark Blue, Gray, Green, Orange, Red, white, Yellow |

| MOQ | 500meter |

UL wire

Welding cables are essential components in various industrial, construction, and automotive applications where reliable and efficient electrical connections are crucial. Among the various types of welding cables available, the H01N2-D and H01N2-E cables stand out as popular choices due to their robust construction and performance characteristics. In this article, we will delve into the differences between H01N2-D and H01N2-E welding cables, shedding light on their distinct features, applications, and advantages.

Cable Construction and Specifications:

H01N2-D Welding Cable: H01N2-D welding cables are known for their flexibility and durability, making them ideal for applications where the cable needs to withstand constant movement, bending, and exposure to harsh environments. These cables are typically made of fine copper strands to ensure flexibility while maintaining a high level of conductivity. The insulation and sheathing materials used in H01N2-D cables are often formulated to provide resistance against abrasion, oils, greases, and UV exposure.

H01N2-E Welding Cable: H01N2-E welding cables share similar characteristics with H01N2-D cables, such as flexibility and durability. However, the key difference lies in the insulation material. H01N2-E cables are designed with ethylene propylene rubber (EPR) insulation, which offers enhanced resistance to high temperatures and mechanical stress. This insulation material enables the cable to withstand higher operating temperatures compared to H01N2-D cables, making H01N2-E cables suitable for more demanding welding applications.

Key Differences:

- Temperature Resistance: The primary distinction between H01N2-D and H01N2-E welding cables is their temperature resistance. H01N2-E cables can tolerate higher temperatures due to the EPR insulation, making them better suited for applications involving more intense welding processes that generate significant heat.

- Application Environments: H01N2-D welding cables are well-suited for general welding tasks, where the operating conditions are relatively standard. They provide the necessary flexibility and durability for routine welding applications. On the other hand, H01N2-E welding cables excel in environments with higher temperature requirements and increased mechanical stress.

- Industrial Sectors: Both H01N2-D and H01N2-E cables find applications in industries such as manufacturing, construction, and shipbuilding. H01N2-D cables are often preferred for less demanding welding tasks, while H01N2-E cables are commonly used in heavy-duty welding operations where elevated temperatures and mechanical challenges are prevalent.

- Cost and Investment: Due to their enhanced temperature resistance, H01N2-E welding cables might come at a slightly higher cost compared to H01N2-D cables. However, this cost difference is often justified by the increased performance and durability offered by H01N2-E cables in specific applications.

Conclusion:

When selecting the appropriate welding cable for a particular application, it’s essential to consider the environmental conditions, temperature requirements, and mechanical stress that the cable will encounter. H01N2-D welding cables offer flexibility and durability for standard welding tasks, while H01N2-E welding cables provide the advantage of withstanding higher temperatures and increased mechanical stress. By understanding the differences between these cable types, professionals can make informed decisions to ensure safe, efficient, and reliable welding operations in various industries.

Categories

- 0.6/1 kv Power Cable (17)

- LS0H/LSZH cable (2)

- PVC Cable (3)

- Rubber Cable (9)

- XLPE cable (4)

- Automotive wire (39)

- American standard wire (9)

- Car Battery Cable (34)

- Euro standard wire (12)

- EV Cable (8)

- Japanese standard wire (7)

- Coil cable (34)

- PUR cable (12)

- PVC cable (3)

- Rubber cable (9)

- Spiral cable assembly (10)

- Flexible control cable (2)

- Genie Parts (5)

- Industrial Wire Cable (33)

- CCC wire (5)

- CE Cable (3)

- Data cable (6)

- Drag chain cable (7)

- Robot cable (2)

- Servo cable (3)

- Special cable (3)

- UL wire (3)

- Media Cable (5)

- Microphone Cable (1)

- Speaker cable (4)

- Other (4)

- Ready to Ship (23)

- Single Core Cable (21)

- CE certificated cable (7)

- Drag chaine cable (2)

- Photovoltaic cable (5)

- PUR flexible cable (3)

- Solar Cable (7)

- UL certificated cable (3)

- Trailer Truck Cable (26)

- Coil Cable Assembly (16)

- Trailer cable (10)

- Wire harness for industry (7)

Producer

Price

As direct sale from our factory, we offer bellow benefits:

- Best price on the market guaranteed !

- The option to modify the product, such as the color, the length, you name it!