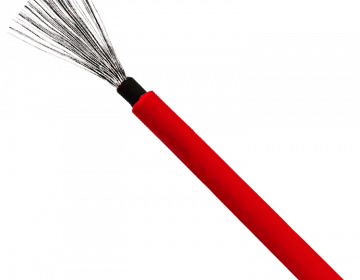

Pv1-f Solar Cable for Photovoltaic Power System, 6mm Halogen-free Double insulated single core wire

Solar cables are intended for use in photovoltaic power supply systems and similar applications as free hanging, movable, fixed installation and buried in ground in constructional covered systems. The cables can be used indoor, outdoor, in hazard explosion areas, in industry and agriculture. They are suitable for applications in equipment with protective insulation (protecting Class 2).

Product Mix

| Conductor | Fine Wire Tinned Copper Conductor according to BS EN 60228:2005 cl. 5. |  |

| Core insulation | UV resistant, cross linkable, halogen free, flame retardant compound for core insulation. | |

| Sheath colour | Red, black or natural | |

| Packaging | Meter marking |

Technical Parameters

| Operating voltage: | 300/500v (H05Z-K), 450/750v (H07Z-K) |

| Maximum operating voltage: | 2500 volts |

| Temperature range : | -40°C to +90°C |

| Advantage : |

very good resistance to oil and chemicals with acid and alkaline resistance |

What is Solar cable ?

Before introducing photovoltaic cable, let’s have a look what is photovoltaic system(PV system).

Solar cable, also called photovoltaic cable or PV wire, is a single-core wire used to interconnect the solar panels of a photovoltaic system. PV systems, or solar panels capture sunlight in order to produce electricity through an energy conversion process. Electricity is produced at the panel and wiring is needed to convey the electrical energy back to a collection point or piece of equipment. Solar wire is a specific kind of wire created for PV applications.

The photovoltaic wire was originally intended to be a single conductor similar in construction to a Type UF (Underground Feeder) or Type USE-2 (Underground Service Entrance wire rated for 90°C wet applications). However, because some solar applications are massive, the amount of power they generate is considered utility scale. This large amount of power requires a large conductor, often called a collector cable, which is addressed by the increases in sizes now allowed for UL Listed Photovoltaic Wire under the UL Subject 4703 revisions.

The new voltage ratings permitted in UL Subject 4703 can now accommodate voltages greater than 1,000 volts. By connecting the direct-current generating panels together in series, the voltage in an entire array can be increased to fairly high levels, which accounts for the higher voltages.

Details

| code | Single Core |

|---|---|

| Color | customized |

| MOQ | 500meter |

| Conductor | copper |

| Temperature (°C) - flexing | -40°C to +90°C |

| Core | Single Core |

| Nominal voltage U0/U | AC : 1,0/1,0 kV DC : 1,5/1,5 kV |

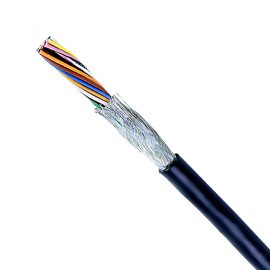

| code | Multi-Core |

|---|---|

| Conductor | copper |

| Nominal voltage U0/U | 300V/500V |

| Temperature (°C) - flexing | -5 to +80℃ |

| Color | Black, Gray, Orange |

| MOQ | 500meter |

| Temperature (°C) - fixed | -40 to +80℃ |

| Core | Multi |

| Brand | KMCable |

|---|---|

| code | Multi-Core |

| Conductor | copper |

| Nominal voltage U0/U | 300V |

| Temperature (°C) - flexing | 70℃ |

| Color | customized |

| MOQ | 500meter |

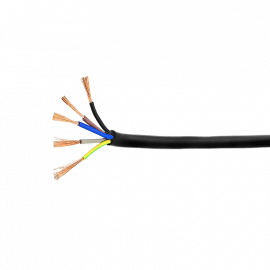

| code | Multi-Core |

|---|---|

| Conductor | copper |

| Nominal voltage U0/U | U0/U 600/1000 V |

| Temperature (°C) - flexing | -50°C to +90°C |

| Color | Black, Gray, Orange |

| MOQ | 500meter |

| Temperature (°C) - fixed | -40 to +80℃ |

| Conductor | Multi stranded annealed bare copper wire or tinned copper wire |

|---|---|

| Temperature (°C) - flexing | -10℃ to70℃ |

| Color | customized |

| Nominal voltage U0/U | 300V/500V |

| MOQ | 500meter |

XLPEinsulatedlow-smokeno-haloganelectriccable

DownloadCategories

- 0.6/1 kv Power Cable (17)

- LS0H/LSZH cable (2)

- PVC Cable (3)

- Rubber Cable (9)

- XLPE cable (4)

- Automotive wire (39)

- American standard wire (9)

- Car Battery Cable (34)

- Euro standard wire (12)

- EV Cable (8)

- Japanese standard wire (7)

- Coil cable (34)

- PUR cable (12)

- PVC cable (3)

- Rubber cable (9)

- Spiral cable assembly (10)

- Flexible control cable (2)

- Genie Parts (5)

- Industrial Wire Cable (33)

- CCC wire (5)

- CE Cable (3)

- Data cable (6)

- Drag chain cable (7)

- Robot cable (2)

- Servo cable (3)

- Special cable (3)

- UL wire (3)

- Media Cable (5)

- Microphone Cable (1)

- Speaker cable (4)

- Other (4)

- Ready to Ship (23)

- Single Core Cable (21)

- CE certificated cable (7)

- Drag chaine cable (2)

- Photovoltaic cable (5)

- PUR flexible cable (3)

- Solar Cable (7)

- UL certificated cable (3)

- Trailer Truck Cable (26)

- Coil Cable Assembly (16)

- Trailer cable (10)

- Wire harness for industry (7)

Producer

As direct sale from our factory, we offer bellow benefits:

- Best price on the market guaranteed !

- The option to modify the product, such as the color, the length, you name it!

Featured Products:

| Weight | 12 kg |

|---|---|

| Dimensions | 55 × 45 × 35 cm |

| Color | Red |

| Power | 9 Volt Alkaline Battery |

| Length | 300M |

![Dip meter, stainless steel Ruler tape cable, without probe(50M) [Part]](https://kmcable.com/wp-content/uploads/2021/07/dip-meter-stainless-steel-ruler-tape-cable-30m-50m-100m-150m-200m-300m-05-1-270x270.jpg)

| Weight | 1.3 kg |

|---|---|

| Color | white, Yellow |

| Response Time | <10 Milliseconds |

| Length | 50M |

| Use For | KMCABLE water level meter |

| Material | Stainless Steel |

| Brand | KMCable |

|---|---|

| Color | customized |

| Length | 200M, 300M, customise |

| Material | Stainless Steel |

| MOQ | 1pc |

| Brand | KMCable |

|---|---|

| Color | Black |

| Conductor | copper |

| Core | Multi |

| Nominal voltage U0/U | customized |

| Temperature (°C) - flexing | -40°C ~100°C |

| MOQ | 3PC. |

| Color | Black, Red |

|---|---|

| Conductor | copper |

| Nominal voltage U0/U | 12V/24V |

| standard | IEC60245, VDE0282 |

| sheath | Neoprene, PVC, Rubber |

| Length | customise |

| MOQ | 100pec |